WHO WE ARE

WHO WE ARE

Pharmaceutical packaging

Carclo and its LifeTech Solutions Innovation Incubator is building a new generation of pharmaceutical primary packaging solutions supported by our capabilities in precision moulding, materials science, medical-grade manufacturing and device-level engineering.

What we make

Under our VialTech Series programme, Carclo is developing a family of innovative pharmaceutical packaging concepts designed to serve injectable, reconstitutable and vial-based therapies, including:

- FusionCap™ – a reimagined vial closure concept with enhanced usability, safety and sealing architecture

- FusionCap™ SMART variant – integrating RFID/NFC capability for vial level control, authentication, and patient support

- PureStop™ – driving stopper engagement, sealing integrity, PFAS free sustainability

- GuardVial™ – next-generation polymer vials designed for strength, clarity and barrier performance

- Future integrated vial, closure system and smart capabilities – engineered as complete primary packaging solution.

Individually, these represent discrete innovations. Together, they define the early architecture of a future Carclo vial

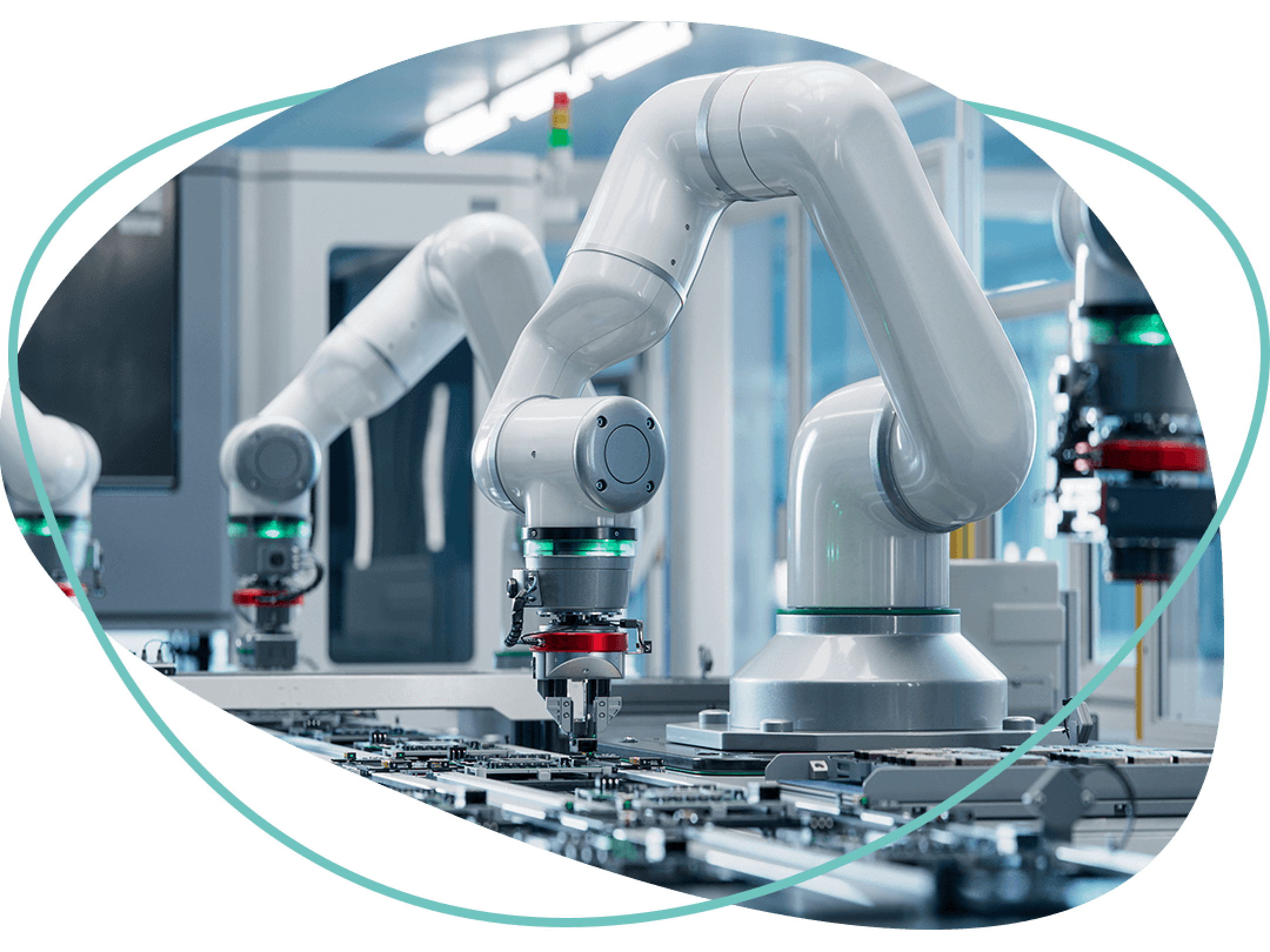

How we make it

Pharmaceutical packaging requires precision, consistency and deep understanding of material behaviour, sealing performance & testing and drug–contact interactions. Carclo approaches this through:

- Production-intent prototyping using C-Mould technology

- Materials science and polymer performance studies

- Sealing performance engineering

- Two-shot moulding technology

- Functional and usability engineering

- Digital enablement via SMART variants

- Future planning in new manufacturing capabilities

Pharmaceutical packaging built on scientific discipline and manufacturability

Materials

The VialTech Series is already grounded in real materials science workstreams, including:

Medical-grade polypropylene (PP) – for closure components and structural elements

High-clarity COC/COP – for future polymer vials

EVA / TPEs – for sealing, flexibility, or hybrid interfaces

Low-surface-energy materials – to reduce stick–slip, friction or contamination risk

Sustainability-aligned materials – mass-balance bio-PP, bio-PE, and future low-carbon polymers

Barrier-performance and chemicalcompatibility studies – aligned with vial contact-layer requirements

Typical programmes

Typical LifeTech programmes relevant to Pharmaceutical Packaging include:

FusionCap closure architecture development and iteration

SMART closure integration with digital ecosystems

Material studies to optimise sealing performance

Exploratory hybrid two-shot concepts (vial tops, rigid-soft assembly)

Concept creation for ClearVial and GuardVial packaging

Future evaluation of Injection Blow Moulding platforms for vial body production

Recent investments

Carclo is steadily building the enablers needed to succeed in this space:

- C-Mould production-intent prototyping, allowing rapid iteration of closure geometries, sealing systems and functional interfaces

- Advanced polymer testing and analytics

- Cleanroom moulding and validation capability appropriate for regulated packaging components

- Engineering expertise from drug delivery and diagnostic consumables, which informs key performance requirements

- Digital enablement capacity through LifeTech’s work on SMART closures and SYNCURA data pathways

- Recruitment of expertise in this space

- Future investments — particularly in injection blow moulding — are under evaluation as platform enablers for polymer vial testing and scale up.

Why it matters

Pharmaceutical packaging is evolving. Vials, closures and sealing systems are no longer passive containers - they are increasingly enablers of:

- Patient safety

- Drug stability

- Supply-chain visibility

- Authentication and anti-counterfeit measures

- Digital health integration

- Sustainability improvements

- Risk reduction in clinical and manufacturing workflows

Pharmaceutical packaging is the next frontier for Carclo’s innovation ambitions.

Core Pharmaceutical Packaging Capabilities

-

Design and engineering of vial closures, hybrid systems and functional sealing interfaces

-

Integration of RFID/NFC into closures (SMART variants)

-

Polymer material selection, optimisation and performance science

-

Production-intent prototyping with C-Mould

-

Controlled-environment moulding for regulated packaging components

-

Future injection blow moulding (IBM) strategy development for GuardVial

-

Sealing performance modelling and validation

-

Rigid–soft interface design (PureStop, hybrid two-shot concepts)

-

Supply-chain visibility and authentication integration

-

Compatibility with existing vial formats and roadmap to proprietary Carclo formats

-

Sustainability impact assessments and material substitution pathways