MARKETS

Recent Investments

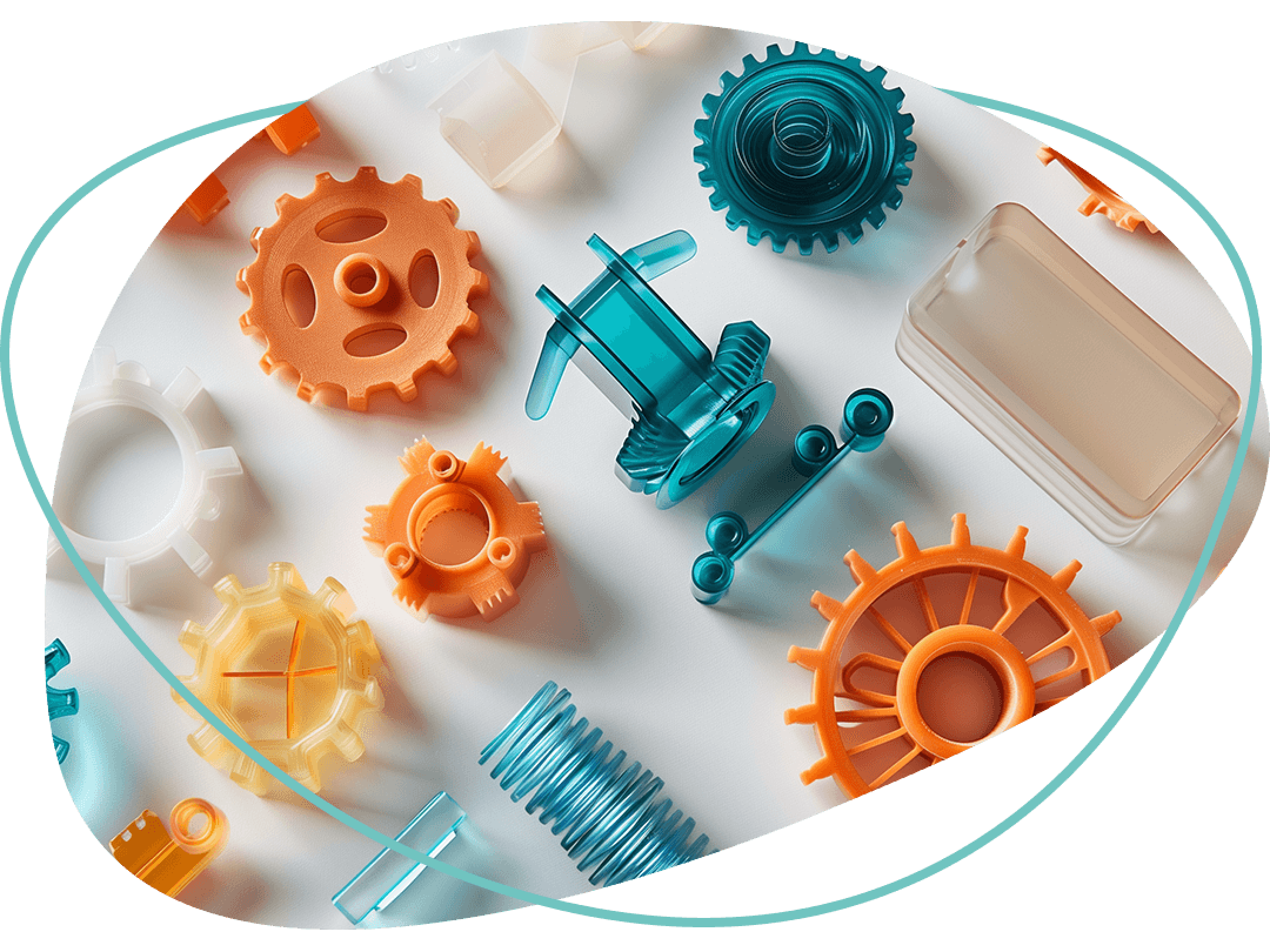

Carclo has made several investments that directly strengthen our IVD capability:

- Cleanroom expansions in both the US and Europe, supporting diagnostic consumables and drug delivery components.

- New all-electric injection moulding machines providing the stability needed for tight-tolerance diagnostic parts.

- Ongoing collaboration with major IVD OEMs that drives continuous improvement in component performance and manufacturability.

- Enhanced materials and analytics capability

- LifeTech Solutions incubator providing a framework to channel future IVD innovation — including low-surface-energy materials, improved fluidics behaviour, and smarter integration with analysers.

Ensuring that the IVD segment is not just a mature revenue stream, but also a platform for future innovation.

Why it matters

In-vitro diagnostics is at the heart of modern healthcare. Every cuvette, tip and cartridge plays a quiet but critical role in supporting positive health outcomes:

- Underpinning reliable diagnostics for millions of patients worldwide.

- Supporting OEMs in maintaining throughput, uptime and result integrity in their systems.

- Positions Carclo as a partner that understands both the device and the diagnostic workflow, not just the plastic part.

IVD is both a foundation and a future opportunity: a place where incremental materials innovation can deliver meaningful performance gains, and where future proprietary concepts emerge.