WHO WE ARE

WHO WE ARE

Light & motion

From our base in Aylesbury, UK, we bring together the complementary strengths of Wipac Aftermarket, Carclo Optics, Carclo Fresnels and Coil, to deliver advanced solutions across automotive, optical, and eye care sectors.

Our expertise spans LED headlamp upgrades and automotive lighting enhancements, precision-moulded secondary optics, PIR Sensor Lenses and high-quality visual aids.

With decades of engineering excellence and state-of-the-art manufacturing, we combine precision, reliability, and innovation to support customers across a wide range of industries worldwide.

What we make

- LED headlamp upgrades and aftermarket lighting solutions that enhance performance, efficiency, and design for automotive applications.

- Precision-moulded secondary optics for LEDs, delivering optimal light control and visual clarity across commercial, architectural, and industrial environments.

- High-quality visual aids engineered to improve everyday readability and comfort.

- PIR Sensor Lenses designed to integrate seamlessly into complex systems, enhancing efficiency and security.

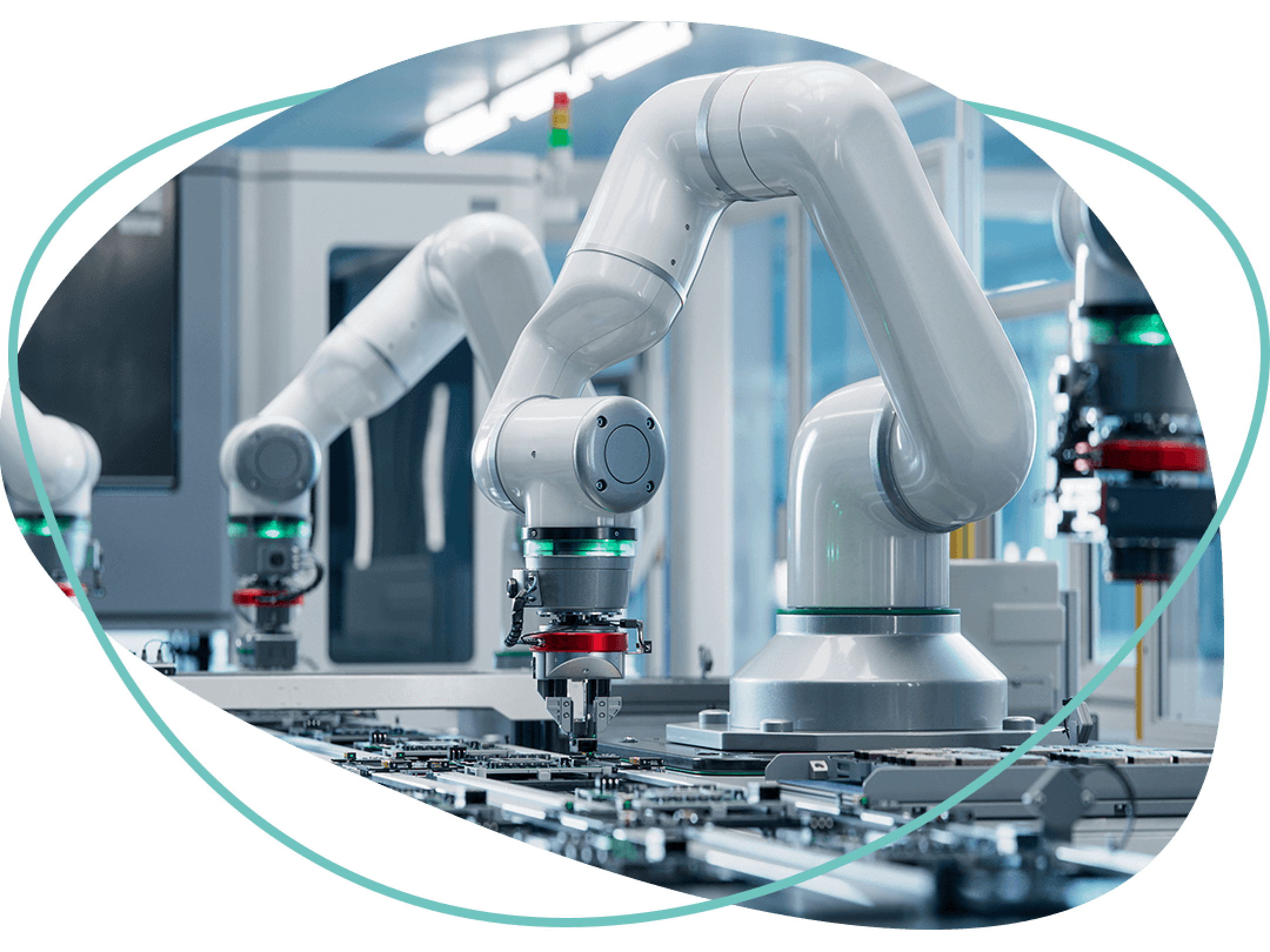

How we make it

Through precision moulding, machining, and assembly processes that ensure consistent optical and mechanical performance across every component.

Using state-of-the-art design and manufacturing software to optimise quality, efficiency, and consistency from prototype through to full production.

With clean, well-managed manufacturing environments and careful handling to protect surface quality and optical integrity.

Materials

- Optical-grade polymers: PMMA, PC, and other high-performance materials for precision-moulded lenses and light guides.

- Metals: aluminium alloys, stainless steels, and specialist materials for precision housings and assemblies.

- Glass and hybrid materials used where optical clarity and durability are critical.

Typical programmes

- Prototype-to-production support for new lighting, optical, and visual aid developments.

- Low-to-medium volume manufacturing with rapid changeover to support diverse product ranges.

- Collaborative design and tooling programmes that optimise optical performance and production efficiency.

Recent investments

People and progress: ongoing investment in staff development is helping to strengthen skills, collaboration, and innovation across all areas of the business.

Technology and tools: the introduction of AI-powered systems is driving greater efficiency, insight, and performance across the board.

Why it matters

Performance: precision-engineered products that enhance visibility, usability, and overall customer experience across automotive, optical, and visual aid applications.

Innovation: continuous investment in design, materials, and smart manufacturing technologies that help customers achieve more efficient, effective, and sustainable results.

Reliability: trusted solutions built on consistency, quality, and long-term value — ensuring our customers can depend on every component, every time.

-

Processes

Injection moulding, CNC machining, polishing, optical coating, assembly, and clean-pack handling.

-

Parts envelope

From micro-scale optical components to large-format moulded lenses and assemblies.

-

Tolerances

Optical and mechanical tolerances verified to meet customer and application requirements.

-

Surface Finish

Precision-polished or moulded finishes for optimal clarity, transmission, and performance.

-

Documentation

Full traceability and certification available, including CoC, inspection reports, and material data.

-

Inspection

Automated and manual inspection to ensure dimensional accuracy and optical quality.

-

MOOs

Available on request for specific product families and validation projects.