WHO WE ARE

Recent investments

To support growing customer demand and strengthen capacity across the division, several major investments have been made:

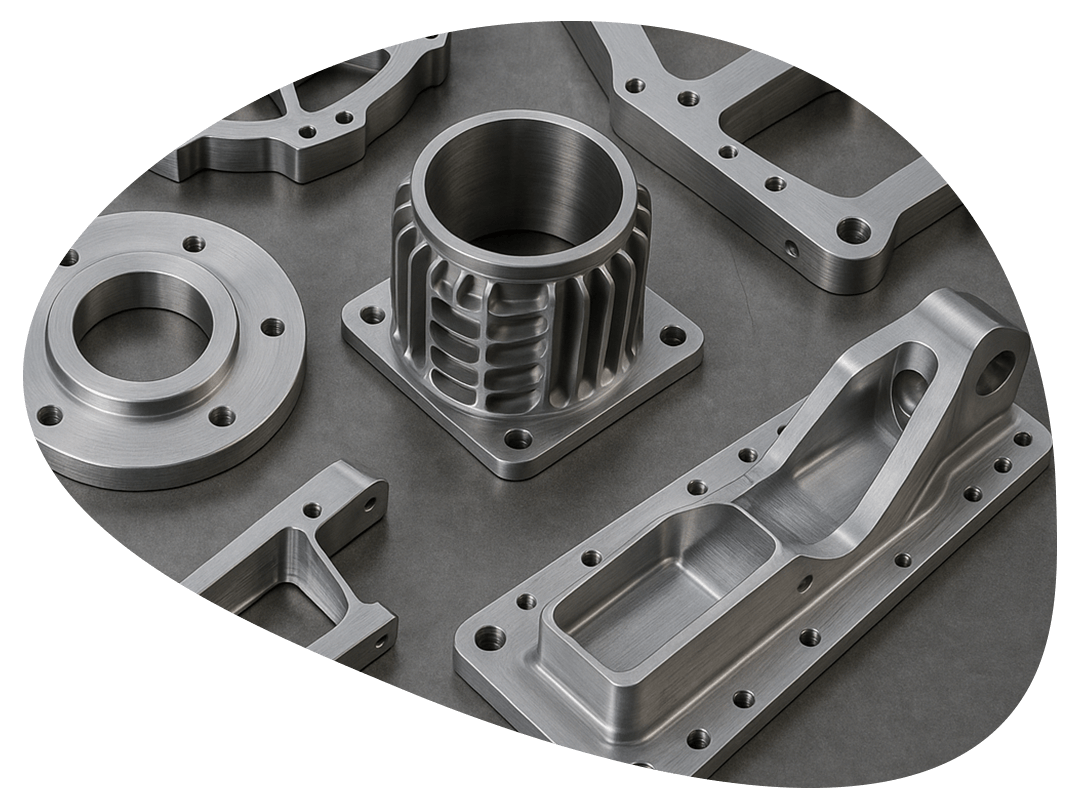

Machining Capacity

- Two new STAR sliding-head CNC lathes installed at Bruntons Aero Products.

- Two new STAR sliding-head CNC lathes installed at Jacottet Industries

Arrestor Rope Manufacturing

- A new 1200-tonne forming press, significantly increasing capability and reliability for safety-critical arrestor-rope components.

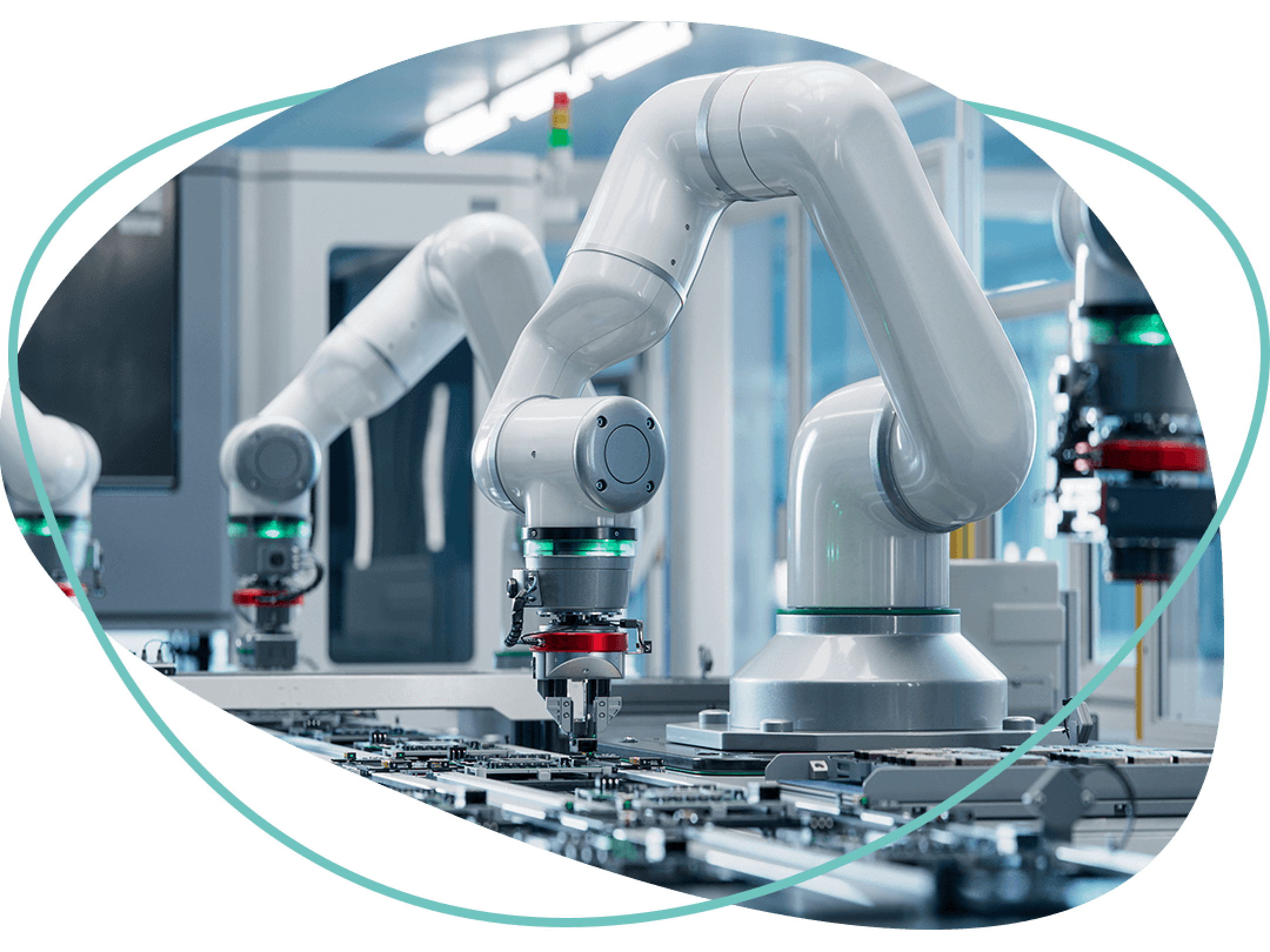

Digital Transformation

- Implementation of Microsoft Business Central across operations, enabling real-time planning, scheduling, materials control, and data visibility across both companies.

These upgrades enhance capability, increase efficiency, and support long-term competitiveness in demanding aerospace markets.

Why it matters

Aerospace customers rely on absolute consistency, quality, and delivery performance. The work carried out by Bruntons and Jacottet supports:

- Aircraft safety, through traceable components built to exacting aerospace standards.

- Operational readiness, particularly for military customers requiring reliable arrestor systems, cables, and critical hardware.

- Global supply-chain resilience, with two highly capable facilities offering complementary capacity within the group.

- Long-term sustainability, with modern equipment, digitalised processes, and a future-focused investment strategy.

By combining heritage craftsmanship with modern manufacturing and digital systems, the Aerospace Division continues to deliver trusted, high-value components to some of the world’s most demanding aerospace programmes.