WHO WE ARE

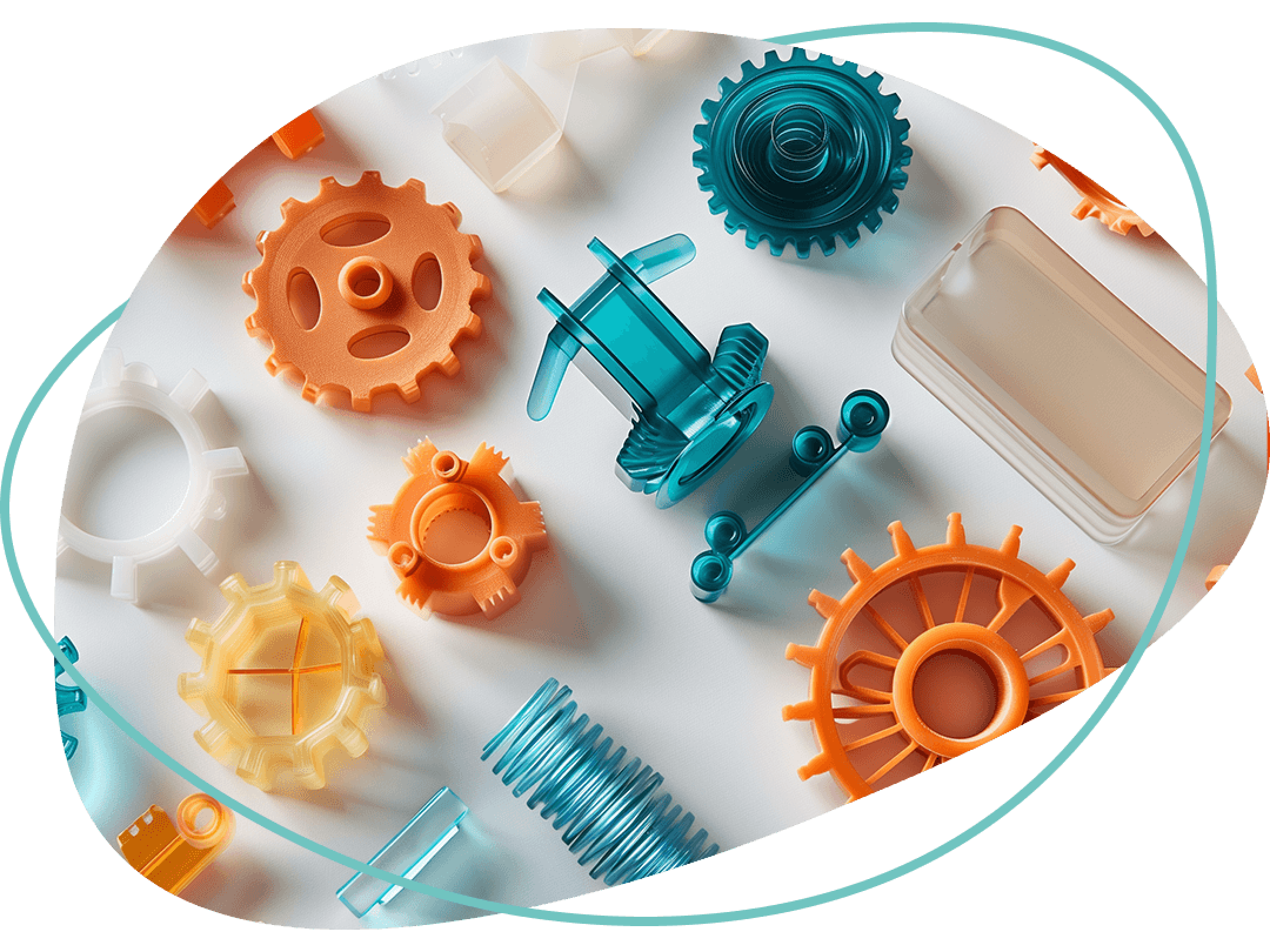

Materials & Typical programmes

Produced from high quality precision tool steels C-Mould supports the full spectrum of medical, engineering & filled polymer grades.

C-Mould’s design & build ensures freedom for all your resin selection decisions.

Recent investments

Carclo has invested heavily in the design, build and aquisition of C-Mould to deliver a strategic capability in product development and high precision scalable production:

• Installation of modular sysrem infrastructure and capacity

• Conformal-cooling design and manufacturing capabilities

• Simulation software and thermal modelling

• Hot-runner systems tuned for modular platforms

• Advanced FANUC all-electric moulding cells

• Integration into the LifeTech Solutions innovation framework

These investments position C-Mould as a central enabling technology for Innovation Solutions.

Why it matters

Speed-to-market and development certainty are critical. Customers often face a slow, expensive transition from

early prototyping to production tooling — with repeated redesigns, changing part behaviour and revalidation loops.

C-Mould eliminates this disconnect because it:

- Delivers production-representative moulding far earlier in the development process

- Enables rapid design evolution without compromising tool performance

- Reduces development cost by avoiding repeated rebuilds of full steel tools

- Allows customers to see statistical variation and cavity reproducibility early

- Provides earlier insight into manufacturability, robustness and scale-up risk

- Supports a clear, scalable pathway from idea → prototype → validation → production

- Accelerates time-to-market while increasing confidence in product performance

For LifeTech Solutions and for customers search for agility without sacrificing quality — C-Mould is one of Carclo’s most enabling technologies.